Ball Charge For Cement Mills

ball charge for cement mills. cement mill ball charging belt SBM Machine. mill charge load calculation 19 Jun 2013 volume loading charge calculation for cement millgrinding media

WhatsApp)

WhatsApp)

ball charge for cement mills. cement mill ball charging belt SBM Machine. mill charge load calculation 19 Jun 2013 volume loading charge calculation for cement millgrinding media

ball chargers for cement mill : ball chargers for cement mills The raw mill will be operate with a much coarser ball charge than the cement mill mainly because of the Get P; Cement Mill Ball Mill Dynamics Forum Cement. Oct 9, 2016 Size reduction in a ball mill is achieved primarily by the motion of the balls in the mill.

ball chargers for cement mills; Send A Message. You can get the price list and a GM representative will contact you within one business day. Ball mill_Henan Mine Machinery Co., Ltd. The ball mill is the key equipment to crush the material after being crushed. This type of mill is equipped with a number of steel balls in its cylinder as grinding

Mill Ball Charger. January 03, 2020. FL provides sustainable productivity to the global mining and cement industries. We deliver marketleading engineering, equipment and service solutions that enable our customers to improve performance, drive down costs and reduce environmental impact. Our operations span the globe and our close to 11,000 employees are present in more than 60 countries.

18/07/2016#0183;#32;Closed Circuit Ball Mill System. Clinker, Gypsum and other desired additives are fed to the ball mill in specific proportions based on the quality requirement. Feed material is ground in the ball mill, discharged and fed to a classifier with the help of a bucket elevator for classification of the ground cement into two streams coarse and fines.

A continuous ball charging solution for your mill. When charging a grinding mill, the standard practice is to dump tons of balls into the mill at once and replace them somewhere between once a shift and once a week. Its an inefficient practice that wastes energy, impacts product particle size distribution and risks breakage of mill linings and grinding media.

11/02/2019#0183;#32;Mike Day Everything About Concrete Recommended for you 27:12 The OK mill the most reliable and efficient mill for raw and cement grinding Duration: 2:47.

ball chargers Storage hoppers and trays for steel ball grinding media Transmin specialises in a range of systems available to safely store and feed (charge) steel balls into mills or conveyors from simple kibbles, through to complex handling systems comprising storage hoppers connected to ball feeders of the cassette or star feeder variety.

how to charge the ball in cement mill. How To Charge Ball In Cement Mill PANOLA Mining . Ball mill charge calculation in cement ball mill grinding media calculation the ball charge mill consists handbook for dry process plants 187 learn more technical notes 8 grinding r p king media or charge in the mill and dm is the diameter of e is a function of the ball media size distribution in the mill..

01/01/2000#0183;#32;The Magotteaux Automatic Ball Charger (ABC) optimizes ball mill performance by controlling ball addition. Each ABC consists of a storage hopper, vibrating feeder, load cells, local control electronics and computer link to the grinding process. The system continuously monitors absorbed power, feed rate and ball consumption to calculate the proper ball addition rate to maintain optimum mill power.

03/03/2015#0183;#32; Ball mill is an efficient tool for grinding many materials into fine powder. The Ball Mill is used to grind many ki...

ball chargers for cement mills is manufactured from Shanghai,It is the main mineral processing solutions. stone crushing machine projectball chargers for cement mills. ShangHai (ball chargers for cement mills) are a professional production of stone crushing and Widely used in Europe, South America, Africa, East Asia and Asia region.

VRM has been a more compact unit is quite smaller about the ball mills thus significantly reducing civil engineering cost about a ball mill plant. Ball mills are factory made and transported to the plant site of the buyer while VRM is built on the site of the cement plant. This helps to reduce cost and complicated logistics issues. The equipment cost is, however, higher for a VRM than a ball mill.

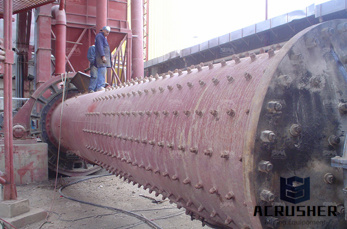

A Ball mill is a horizontal cylinder partly filled with steel balls (or occasionally other shapes) that rotates on its axis, imparting a tumbling and cascading action to the balls. Material fed through the mill is crushed by impact and ground by attrition between the balls. The grinding media are usually made of highchromium steel. The smaller grades are occasionally cylindrical (quot;pebsquot;) rather than spherical.

Ball top size (bond formula): calculation of the top size grinding media (balls or cylpebs):Modification of the Ball Charge: This calculator analyses the granulometry of the material inside the mill and proposes a modification of the ball charge in order to improve the mill efficiency:

Cement Milling. Cement milling is usually carried out using ball mills with two or more separate chambers containing different sizes of grinding media (steel balls). Grinding clinker requires a lot of energy. How easy a particular clinker is to grind (quot;grindabilityquot;) is not always easy to predict, but large clusters of belite due to coarse silica in the feed are difficult to grind.

The development of Loesche vertical roller mills for large capacity grinding is discussed. With 3+3 technology, the company is prepared to replace 2 to 3 ball mills in cement grinding plants with

cement ball mills charging le . Calculation Of Grinding Media Charging Ball Mill Of Cement. media charging in cement mills, cement ball mills charging le,media charging in ball mill in cement Cement mill Wikipedia A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement Most cement is currently ground in ball mills

WhatsApp)

WhatsApp)