Know The Ball Mill In Mining

Ball Mills | Industry Grinder for Mineral Processing

WhatsApp)

WhatsApp)

Ball Mills | Industry Grinder for Mineral Processing

Jan 30, 2018#0183;#32;The ball miller machine is a tumbling mill that uses steel milling balls as the grinding media, applied in either primary grinding or secondary grinding applications. The feed can be dry or wet, as for dry materials process, the shell dustproof to minimize the dust pollution.

For ball mill, the grinding force of steel ball to ore is less than the impact, because the contact area is small between balls and mineral. Thus, the throwing motion of ball can produce a large impact, but it need a high rotate speed and has a higher power consumption. But for rod mill, grinding effect is better which need a lower rotate speed and has a lower power consumption. Xinhai produce

Advanced Controller for Grinding Mills: Results from a Ball Mill Know More. disturbances in a mining environment, significantly improve throughput while Results of using this advanced controller on a ball mill circuit operation in a copper years, modelbased control techniques have been successfully used in the process equipment upstream (such as primary crushers) or downstream (such as

Because of the arduous nature of the ball mill application and the time it takes to manufacture these colossal bearings, OKeefe says having a reliable supplier is essential.

Ball mill. A typical type of fine grinder is the ball slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the tumbling balls. Ball mills normally operate with an approximate ball charge of 30%. Contact Supplier

A VSI mill throws rock or ore particles against a wear plate by slinging them from a spinning center that rotates on a vertical shaft. This type of mill uses the same principle as a VSI crusher.. Tower mill. Tower mills, often called vertical mills, stirred mills or regrind mills, are a more efficient means of grinding material at smaller particle sizes, and can be used after ball mills in a

A Ball Mill grinds material by rotating a cylinder with steel grinding balls, causing the balls to fall back into the cylinder and onto the material to be ground. The rotation is usually between 4 to 20 revolutions per minute, depending upon the diameter of the mill. The larger the

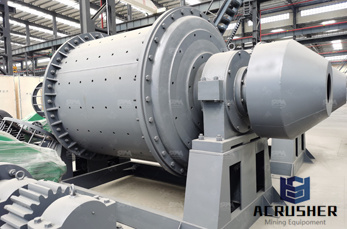

Ball mill, also known as ball grinding machine, a wellknown ore grinding machine, widely used in the mining, construction, aggregate start the ball mill business since 1985, supply globally service includes design, manufacturing, installation, and free operation training.

According to a ball mills working principle, materials are mainly ground by its grinding media. Either too many or too less grinding media will affect the grinding effects so that a ball mill should be fed with a proper number of grinding media according to scientific and reasonable calculation. Notice on the Selection of Ball Mills

However, do you really know about ball mills? Next, the introduction of a ball mill will be for you by our experts. The Structure of a Ball Mill Although there are different types of ball mills due to the differences in manufacturing method, specification, discharging method, they generally have the same structure, which mainly consists of the feeding devices, support devices, rotary parts

Jun 14, 2018#0183;#32;As a result, a number of machines have been invented to bring about maximum results with regard to obtaining the much needed resource, gold. One of such equipment is the ball mill. Below is the writeup of how a ball mill works, is used to crush ore and an explanation regarding its effectiveness in gold mining.

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A section cut thru of ball mills . A ball mill consists of a hollow cylindrical shell rotating

About Ball Mill in Mining Market: Market Analysis and Insights: Global Ball Mill in Mining MarketThe global Ball Mill in Mining market size is projected to reach USD million by 2026, from USD million in 2020, at a High CAGR during report focuses on Ball Mill in Mining volume and value at the global level, regional level and company level. From a global perspective, this report

To know the Ball Mill (Mining) Market by pinpointing its many subsegments. To profile the important players and analyze their growth plans. To endeavor the amount and value of Ball Mill (Mining) submarkets, depending on key regions (various vital states).

Ball mill Know More. A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from Size: The smaller the media particles, the smaller

Sep 24, 2020#0183;#32;iCrowd Newswire Sep 24, 2020. has published a new report titled Global Ball Mill in Mining Market Growth that includes the current status of the global market and predicts its growth and each and every fundamental thing across essential regional markets. The report distinguishes, estimates, and examinations the rising patterns along with significant drivers,

11/07/2019#0183;#32;A Ball Mill grinds material by rotating a cylinder with steel grinding balls, causing the balls to fall back into the cylinder and onto the material to be ground. The larger the diameter, the

WhatsApp)

WhatsApp)