Gold refining process flow movie YouTube

#0183;#32;Gold Refining process flow explained in details

WhatsApp)

WhatsApp)

#0183;#32;Gold Refining process flow explained in details

process flow diagram of gold plant . process flow diagram of gold plant (14 Jun 2012) Gulin supply Mining and construction equipment for mineral handling.

Gold ore . Prominer maintains a team of senior gold processing engineers with expertise and global experience. These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of optimal and costefficient process designs.

gold process flow diagram OneMine Mining and Minerals gold process flow diagram plant flow diagram. flow diagram for Case 2 Process mineralogy as a tool in modelling mineral processing SDIMI Conference Gold Coast, QLD

A process flow diagram (PFD) is a diagram commonly used in chemical and process engineering to indicate the general flow of plant processes and equipment. The PFD displays the relationship between major equipment of a plant facility and does not show minor details such as piping details and designations. Another commonly used term for a PFD is a flowsheet

gold mine equipment flow chart Ore Mining. bentonite wet processing plant pdf #183; Chromite ore beneficiation plant turkey #183; XZM Series You can expect various gold mine equipment flow chart. Mobile gold mine equipment is made for flexible application in

#0183;#32;Gold processing, preparation of the ore for use in various products.. For thousands of years the word gold has connoted something of beauty or value. These images are derived from two properties of gold, its colour and its chemical colour of gold is due to the electronic structure of the gold atom, which absorbs electromagnetic radiation with wavelengths less than 5600 angstroms

gold plant process flow diagram. The design adheres to the principle and design concept of quot;environmental protection, safety, reliability, high efficiency, intelligence, energy saving, complete setquot;, adopts advanced design methods, and adopts the world''s new mobile crushing station technology in the design, according to the needs of customers, to create greater value and profit for availability.

currently operating plant. Process overview and description The CIP process A blockflow diagram of a typical CIP plant for a nonrefractory gold ore is shown in Figure 2. Table I and Table II illustrate the capital and operating cost breakdowns for a typical South African gold plant. These figures are not a standard but reflect the nature of

The process design of gold leaching and carboninpulp. currently operating plant. Process overview and description The CIP process A blockflow diagram of a typical CIP plant for a nonrefractory gold ore is shown in Figure 2. Table I and Table II illustrate the capital and operating cost breakdowns for a typical South African gold plant.

#0183;#32;The process flow diagram. Image: gold processing flow chart,Gold Ore Processing Plant Equipment For:

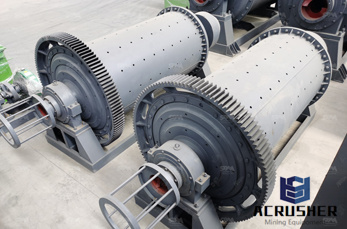

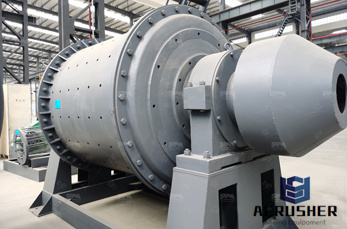

Simple Process Flow Diagram Iron Ore Process Plant Process flow chart for iron ore dry ball mill processFeb 01, 2018 us 5,000 20,000 sets 1 setsets 5 tons small scale gold processing plant for rock gold mining minProduction flowchart 4Ball mill machine in designing process flow for various

Prior to this concentrate trucked to Gidji was also treated in one of two circulating fluid bed roasters at 650#176;C. Commissioning of the 30tph UFG Mill completely replaced roasting, eliminating atmospheric emissions from the Gidji Processing Plant. Extracting the Gold. The Carbon In Pulp (CIP) process is the next stage in the recovery circuit.

The process flow diagram. Image Mining Technology. The process flow diagram. The process flow diagram. The processing plant at Cerro Vanguardia gold and silver mine in Argentina Back to Project Details. Read More

Gold processing plant flow sheet

Gold extraction refers to the processes required to extract gold from its may require a combination of comminution, mineral processing, hydrometallurgical, and pyrometallurgical processes to be performed on the ore.. Gold mining from alluvium ores was once achieved by techniques associated with placer mining such as simple gold panning and sluicing, resulting in direct recovery of

treated in a separate stream at Kopanang Gold Plant. The Kopanang Gold Plant is a modern plant that uses millleachCIP electrowinning processes. The gold from the electrowinning process is smelted centrally in another plant situated 5 km away from Kopanang. The quality of the final bullion is affected by the presence of base metals. This project

The gold grade in the ore is /t, mainly fine particles, and little microparticles. Most of which are concentrated in the range of Natural gold is mainly embedded in pyrite, mainly inclusion gold (%), followed by cracked gold (%). Mine PreDevelopment Site Inspection for a Gold Mine. 2. Processing Plant

Recommended process flow sheet diagram of gold plant. FLOWSHEET DEVELOPMENT FOR GOLD OREBODIES. Many modern gold plants incorporate gravity circuits as part of their overall flowsheet, and it is estimated that about 10% of the new gold produced each year is recovered by this technique.

WhatsApp)

WhatsApp)