Clirik HGM micro powder grinding mill YouTube

#0183;#32;Superfine Vertical Mill, Micro Powder Grinding MIll Working principle Duration: 0:44. hi hi 399 views. 0:44. 3 minutes learn how Raymond mill works Duration: 1:50.

WhatsApp)

WhatsApp)

#0183;#32;Superfine Vertical Mill, Micro Powder Grinding MIll Working principle Duration: 0:44. hi hi 399 views. 0:44. 3 minutes learn how Raymond mill works Duration: 1:50.

Micro grinding with ultra small micro pencil grinding

Grinding is an abrasive machining process that uses a grinding wheel as the cutting tool.. A wide variety of machines are used for grinding: Handcranked knifesharpening stones (grindstones)Handheld power tools such as angle grinders and die grinders; Various kinds of expensive industrial machine tools called grinding machines; Bench grinders

Grinding is an abrasive machining process that uses a grinding wheel as the cutting tool. A wide variety of machines are used for grinding: Handcranked knifesharpening stones Handheld power tools such as angle grinders and die grinders Various kinds of expensive industrial machine tools called grinding machines Bench grinders Grinding practice is a large and diverse area of manufacturing and

The final fineness of the grinding materials can be adjusted between 300meshes and 3000 meshes which the product fineness can reach D975m. If you want to know more about our micro powder grinding mill, please leave your message on our website, and our technical staff will contact you soon.

Recently, micro aspherical glass lenses are required for electric devices, optical devices and advanced optical fiber transmission equipments. The glass lenses are manufactured with glass molding method by using ceramics dies such as tungsten carbide and therefore molding dies are most important. The ceramics molding dies must be ground ultraprecisely with micro diamond wheel.

#0183;#32;Micro grinding offers a high potential when machining micro structures in hard and brittle materials. In this context, a new machine tool the nano grinding center was developed, which allows to manufacture and apply ultra small micro pencil grinding tools without reclamping.

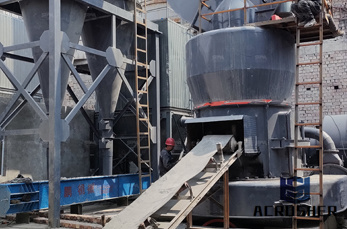

The working principle of Micro powder grinding mill/micronizer. Shanghai Clirik. Machinery Co.,Ltd is specializing in research, manufacture and sales of all kinds of mining equipment. Our company has already formed a full set of modern production line, equipped with intelligent,

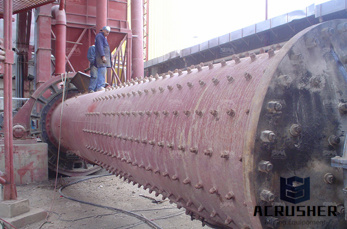

The Micro Pulverizer consists of a rotor assembly fitted with hammers and operates generally at high speeds. A cover fitted with a liner, a retaining screen at the point of mill discharge and a feed screw mechanism whereby the unground material is uniformly fed to the grinding chamber.

Manual Grinding The manual method is useful when automatic equipment is not available or when the depth of grinding is critical. Cross sections of microelectronic devices, such as multiplayer packages, often must be ground to a specic depth.

Pyrophyllite micro powder grinding mill also named Threering fourring mediumspeed micro powder grinding mill is for superfine grinding. materials with hardness less than 6 in Mohs scale and humidity less than 6 percent such as. kaolin, limestone, basalt,

The operation of the microgrinding is started by the motor. An important factor of the motor starting is the magnitude of the current. When the current increases, it will increase the

Micro powder grinding plant is consisted of crushing part, grinding part and dust abolishing equipment and so on. The powder processing plant has applied negative pressure principle designs, effectively prevent the outleakage of dust. In the end of powder processing process, the micro powder grinding plant has installed dust cleaner with most advanced technology.

This article aims to describe the working principle of a jet mill. A jet mill, also called fluid energy mill, is used for solid material micronization. Micronization is a term used to describe size reduction where the resulting particlesize distribution is less than 10 microns.

A grinding machine, often shortened to grinder, is one of power tools or machine tools used for grinding, it is a type of machining using an abrasive wheel as the cutting tool. Each grain of abrasive on the wheel''s surface cuts a small chip from the workpiece via shear deformation. Grinding is used to finish workpieces that must show high surface quality and high accuracy of shape and dimension. As the accuracy in

#0183;#32;HGM Micro Powder Grinding MIll is the new type mining equipment for making micro powders, fine powderswhich is widely applied in the industries of metallurg...

working of micro diamond grinding Microgrinding 4m association . Microgrinding is a material removal technique by means of mechanical force used for A particular technique is referred to as Nanogrinding where diamond in the fabrication technology of grinding tools has led to the application of grinding .

Working principle of Grinding Machine: The working principle of a grinding machine is quite easier to understand.. In a grinding machine, there is an electric motor which supplies the motion power to the grinding wheel with the help of a belt and pulley.. So when we start the electric motor the motor rotates at a certain rpm ( RPM, it may change according to the types of grinding

In Booth N237288, Sch#252;tte MSA, LLC (Jackson, MI) will showcase their 325linear 5axis CNC grinder with extended X and Yaxis movement plus two auxiliary slides for workpiece clamping and improved grinding wheel guidance over the entire machining envelope. Micro tools, gun drills, hob cutters and complex geometries can be accommodated on this machine, which typically operates in the range of

Centerless grinding workblade angles range from 0 to 45 degrees. For most centerless grinding applications, a top blade angle of 30 degrees seems to provide the best results. quot;The basic rule is the steeper the angle of the blade the faster the rounding action,quot; says Mr. Payne. quot;There are limits, however.

WhatsApp)

WhatsApp)