southern province ore factoryclassifier gold flotation

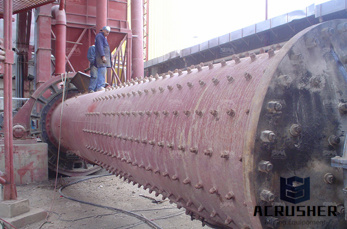

Hydraulic Motor Driving Center Thickener. Hydraulic Motor Driving Center Thickener. Grid Type Ball Mill

WhatsApp)

WhatsApp)

Hydraulic Motor Driving Center Thickener. Hydraulic Motor Driving Center Thickener. Grid Type Ball Mill

Mineral processing Mineral processing Dewatering: Concentrates and tailings produced by the methods outlined above must be dewatered in order to convert the pulps to a transportable state. In addition, the water can be recycled into the existing water circuits of the processing plant, greatly reducing the demand for expensive fresh water. Filtration is the separation of a suspension into a

In the field of extractive metallurgy, mineral processing, also known as ore dressing, is the process of separating commercially valuable minerals from their ores History. A set of Cornish stamps. This section needs Sensor based sorting has found application in the processing of nickel, gold, copper, coal and diamonds. Dewatering

15/3/2018#0183;#32;Technically all ore processing falls under the field of extractive metallurgy, mineral engineering, mineral processing, also known as mineral dressing or ore dresing . It is the process of

Gold extraction refers to the processes required to extract gold from its may require a combination of comminution, mineral processing, hydrometallurgical, and pyrometallurgical processes to be performed on the ore.. Gold mining from alluvium ores was once achieved by techniques associated with placer mining such as simple gold panning and sluicing, resulting in direct recovery of

Kariba minerals limited is a mining company and has long been a reliable source of highquality amethyst for major manufacturers of gemstone related products the company is owned 100 show more senior mining engineers at dangote cement zambia limited lumwana mining company limited lmc a copper mining company owned by barrick gold. READ MORE

13/11/2020#0183;#32;Most ore, however, is contained within hard rock that requires heavy duty crushing. Mobile jaw crushing machine processing ore. The goal of comminution is to crush the ore into small particles that contain only one mineral. Dry crushing ore to ~15 mm particles is carried out on crude ore by compression and impact force.

AMETHYST MINING AND PROCESSING | Kariba . The lower grade amethyst is stockpiled to provide bulk feed for the washing plant. Higher grades of amethyst Amethyst ore from the mines is taken to a washing . Gold Mined Dust Washing Contact Supplier

Gold CIL process. Graphite mineral processing flowsheet. Fluorite flotation process. PbZn ore dressing process. Magnetite Separation Production Line. Gold flotation process. Acquaintance with us. Products gt; More than 600 kinds of mining. equipment .

Metal Mineral Beneficiation Process. Xinhai has been committed to providing customers with more professional services in the turnkey solutions for mineral processing plant, optimized its services continually, and formed its own set of service system, besides, Xinhai set up Mining Research and Design Institute, ensuring the smooth operation in plant service.

Mineral processing is a process that valuable constituents of an ore are concentrated by means of a physical separation process. Welcome to Beijing HOT Mining Tech Co., Ltd; sales +86 28 ; The Introduction of Placer Gold Ore Dressing Technology and Equipment

Up to now, with 2000 servied mine projects, 500 mineral processing EPC+M+O projects, 70 kinds of ores mining technologies and experience and 112 patents, Xinhai has established multiple overseas offices in Asia, South America and Africa and exported to more than 90 countries and regions.

Gold mineral flotation normally adopts one stage grindingflotation process, but stages grinding and flotation for ore with uneven distribution. Grinding fineness of gold For the gold wrapped in sulfide minerals, sulfide ore reaches monomer dissociation; but for the gold with gangue, grinding fineness should reach gold monomer dissociation.

Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore. By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%.

The annual output of heavy placer gold in the gold ore dressing plant accounts for about 25% of the annual gold output. When the coarsegrained gold enters the leaching system, the process flow cannot be satisfied due to the long leaching time required, which

Xinhai Gold CIP Processing. As one of the gold ore dressing processes, Xinhai CIP (Carbon in Pulp) process is extremely popular with various gold ore dressing plants because of its high adsorption rate, high recovery rate and low investment costs. Compared with other gold ore dressing processes, Xinhai CIP process not only eliminates the

Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore. By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%.

ore gold mining machine made of usa; mining equipment mobile crusher screen from joda india; tph stone crusher price in brazil; jaw crusher meaning in bengali; ore dressing gold processing kariba; jaw crusher for sale in europe; high quality ball mill pr for sale; gold and copper ore dressing in mali; jig for silver ore heavy; concrete crusher

Used Ballmills For Sale King 2 Units UNUSED FL 27'' x 46'' ( ID x L) Gearless Ball Mills with MW (20500 kW) GMD Motors Manufact

WhatsApp)

WhatsApp)