Limestone Its Processing and Application in Iron and Steel Indust

Limestone Processing FEECO International Inc.

WhatsApp)

WhatsApp)

Limestone Processing FEECO International Inc.

process of limestone for cement production. Drilling And Blasting Of Limestone For Cement. Cement production. Bricklayer Joseph Aspdin of Leeds, England first made portland cement early in the 19th century by burning powdered limestone and clay in his kitchen stove With this crude method, he laid the foundation for an industry that annually processes literally mountains of limestone, clay

On February, Kohgiluyeh and Boyer mad governor along with a group of high authorities of the province visited the process of construction project of Lar Mountain Limestone Factory located in Charam city of Kohgiluyeh and Boyermad province.

offers 840 limestone processing factory products. About 1% of these are other food processing machinery. A wide variety of limestone processing factory options are

Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 #176;C in a cement kiln.

The raw material is limestone, and the biggest size is 850mm. The first of limestone crushing production line is feeding, limestone by the forklift was poured into the silo, and then slipped into the vibrating feeder, this feeder is a double grate structure, and it has a prescreening function.

limestone quarrying process . Quarrying Limestone Process. a union of texas limestone producers: the result of a merger between two texas limestone producers, rlf salado quarries, llc produces 600

Limestone Crushing Process. Because tthe whole Cement Manufacturing Process is very complied, so I can only briefly limestone crushing process. Therer are so many different types of limestone crusher, I will just choose Impact Crusher as an example to briefly explain.

Sugar cane and sugar beets are harvested and processed with water to form raw juice, which has low pH and contains dissolved impurities. Hydrated lime is added to the juice to raise the pH and to react with the impurities to form insoluble calcium organic compounds that can be removed.

#0183;#32;The cement manufacturing process involves several key steps, including preparing the raw materials, grinding the materials together, heating the newly formed clinker in a kiln, and finishing the cement with fine of the main ingredients used to make cement include limestone, clay, shale, iron, and manufacturing techniques will use either wet or dry grinding, but

Chronic respiratory symptoms among workers at a limestone factory (1)Department for Public Health and Primary Health Care, University of Bergen, Limestone processing is a global industry, 60% originate from the manufacturing process that converts limestone

Can Too Much Limestone Kill PlantsHome GuidesSF . Soil Environments Most plants and grasses prefer slightly acidic soil with a pH of 60 to 65 When limestone drives up soil pH excessively the capacity for nutrient exchange between plant roots and their environment is negatively affected Potassium magnesium and several other trace elements become bound in the soil

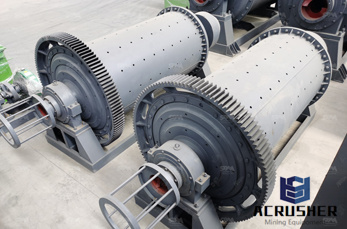

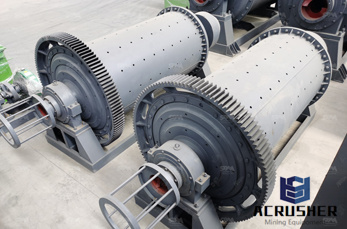

Limestone Processing Issues: Abrasive and Prone to Clumping. A drying process is often used to precondition limestone rock for subsequent manufacturing steps. Like most rocks, limestone is abrasive as a raw material. As a result, heavyduty rotary dryers are recommended to handle limestone

From its varying composition, to its abrasive nature, limestone requires an engineered process solution, combined with heavyduty equipment. Thats why we not only offer limestone processing equipment, but can also help develop a limestone process that works around your unique source of limestone.

The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays. A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km.

Our Solutions About Limestone Process. 600 . production process of crushed Get Price Here ! Pig iron Wikipedia, the free encyclopedia which is a large and cylindershaped furnace charged with iron ore, coke, and limestone. is known as refined pig iron, to the ductile iron process.

Limestone Production Process. As stated above, limestone can used in three forms and as a result the limestone will go though several processes. Here are the basic processes: quarrying of limestone, washing and selecting limestone for further uses, grinding of limestone, calcination of limestone, and slaking of quicklime.

WhatsApp)

WhatsApp)