Cyanide Leaching Tank / Gold Leaching Equipment,

Cyanide Leaching Tank / Gold Leaching Equipment, US 39000 39999 / Set, years, Energy amp; Mining, from Shandong Xinhai Mining Technology amp; Equipment Inc. on

WhatsApp)

WhatsApp)

Cyanide Leaching Tank / Gold Leaching Equipment, US 39000 39999 / Set, years, Energy amp; Mining, from Shandong Xinhai Mining Technology amp; Equipment Inc. on

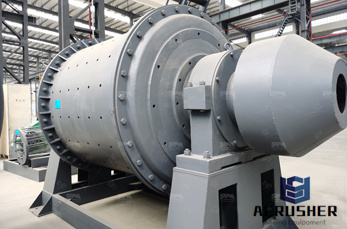

Leaching agitaion tank is a leaching equipment for cyanide leaching by referring the USA technical design Effective Volume 6395m 3 Product Improvement Leaching agitation tank for gold extraction with double impeller, uniform mixing, low energy consumption the impeller coated by rubber, long service life multi points to give gas, uniform

Leaching agitaion tank is a leaching equipment for cyanide leaching by referring the USA technical design Effective Volume 6395m 3 Product Improvement Leaching agitation tank for gold extraction with double impeller, uniform mixing, low energy consumption; the impeller coated by rubber, long service life; multi points to give gas, uniform

300Tpd Gold Heap Leaching Gold Cyanide Process Plant. 300tpd gold heap leaching gold cyanide process plant us 10000 90000 set 15 years 1 year manufacturing plant energy amp mining nigeriasource from xian desen mining machinery equipment co ltd on alibabacom Gold Leaching Tank Gold Leaching Tank Suppliers And

Product Description. Double impeller leaching tank including motor, cycloidal planetary gear speed reducer, bearing block and agitating shaft, and the agitating shaft equipped with a double impeller, from the top view the impeller rotating clockwise, each impeller composed of 4 blades, and the angle of the top blade and the below one is 45 degree. Doubleimpeller leaching tank is a equipment used for gold

The leaching efficiency is increased much because the gold bearing solution is discharged out of the leaching tank in time and the tank is filled by barren solution. Because of batch operation, a battery of tanks work by turns. MerrillCrowe Process Equipment. The depurate pregnant solution enters the closed circular tank with the agitator and

Leaching agitation tank is a leaching equipment for cyanide leaching by referring the USA technical design. Leaching agitation tank for gold extraction with double impeller, uniform mixing, low energy consumption; the impeller coated by rubber, long service life; multi points to give gas, uniform inflation.

The leaching agitation tank is mechanical agitation machine used in cyanide leaching operation of gold mine. The working principle of leaching agitation tank is: with dual impellers rotating and agitating, ore pulps move downward and then diffuse along damping plate. Air is fed in tank from the lower end of shaft, and blended with ore pulps to form uniform suspending mixed liquid.

and type of equipment needed for a thiosulphate leaching flowsheet is very similar to a conventional cyanide leach. SGS is a global technical leader in the field of thiosulphate leaching, and our laboratory and industry experts have spent years designing and developing the technique into a viable alternative to cyanide for some goldbearing ores.

203 gold mining cyanide leaching tank products are offered for sale by suppliers on, of which leaching tank accounts for 1%, other mining machines accounts for 1%. A wide variety of gold mining cyanide leaching tank options are available to you, There are 6 suppliers who sells gold mining cyanide leaching tank on, mainly located in Asia.

Products Leaching Agitation Tank Carbon Screen Washing Thickener Desorption Electrolysis System AdvantagesCancel the solidliquid separation equipment, High gold recovery rate; Activated carbon counter current absorption, High adsorption rate

Air is fed in tank from the lower end of the shaft and blended with ore pulps to form uniform suspending mixed liquid. (2) In the gold cyaniding process, leaching agitation tank is applied to leach and carbonabsorb ore pulps whose fineness is 200 meshes and whose density is less than 45%. Under similar circumstance, it is also applied to agitation and leaching in metallurgy, chemical and light industry.

Leaching Agitation Tank Introduction: Leaching agitaion tank is a leaching equipment for cyanide leaching by referring the USA technical design. Volume :6395m3 Improvement:Leaching agitation tank for gold extraction with double impeller, uniform mixing, low energy consumption; the impeller coated by rubber, long service life; multi points to give gas, uniform inflation.

The agitation leaching method is to concentrate the slurry, obtained after grinding and classifying of the goldcontaining ore, to a suitable concentration, place it in a leaching tank, add a cyanide solution, and aerate to carry out leaching. The main equipment used in the agitation leaching process is a cyanide leaching tank.

gold leaching tank, Find Quality gold leaching tank and Buy gold leaching tank from Reliable Global gold leaching tank Suppliers from mobile site on

This kind of agitating and leaching tank has low body, high leaching speed of gold and low consumption of cyanide. At present, SJ type double impeller leaching and agitating tank is mainly used in our country, which belongs to mechanical and air mixed agitating and leaching tank, and the rotating speed of impeller is relatively low.

Gold Cyanide Leaching Plant Gold Leaching Tank : Doubleimpeller leaching tank is a equipment used for gold cyanidation leaching process and absorption, two transmission ways, one is the planetcycloid reducer drive; the other is the plane envelope reducer drive.

Run of mine Ore Cyanide Machine Dressing Equipment Cyanide Leaching Tank Gold Enrichment Machine Leaching And Agitation Tank, Find Complete. Live Chat. The process design of gold leaching and carbon in pulp SAIMM. as hydrogen cyanide. The leaching of gold can be conveniently represented by the Elsener equation: [1].

Add to Compare. Product Information carbon in leaching plant Doubleimpeller agitation leaching tank is an equipment used for gold cyanidation leaching process and absorption. It has two transmission ways, one is the planetcycloid reducer drive; the other is the plane envelope reducer drive. The design of this device keeps the impeller lowspeed moving, reducing the possibility of wearing or

Due to the stirrer paddle of previously installed double impeller agitation tank is a bit small, the speed is low and pulp agitator is uneven, which are against gold leaching. Then Xinhai contracted its cyanide process. Xinhai updated equipment with larger stirring paddle, and added breath prevention device at the bottom of the hollow shaft. Because the excellent ventilation in center and even agitation of sodium cyanide, the gold leaching

WhatsApp)

WhatsApp)