Effect of ball milling time on microstructures and

Effect of ball milling time on microstructures and mechanical properties of mechanicallyalloyed ironbased materials May 2010 Transactions of Nonferrous Metals Society of China 20(5):831838

WhatsApp)

WhatsApp)

Effect of ball milling time on microstructures and mechanical properties of mechanicallyalloyed ironbased materials May 2010 Transactions of Nonferrous Metals Society of China 20(5):831838

The effect of different milling time on thermoelectric properties of bismuth telluride (Bi2Te3) was investigated. The nanomaterial was prepared by varying the ball milling time and followed by hot

obtained after 50 h of the ball milling time. In order to get more information about the effect of ball milling time on the distribution of Mn. Ti powder particles embedded into the host MgH 2 matrix; intensive STEMEDS Xray elemental mapping were performed for all the samples after ball milling time. Figure 3 presents the

The high energy ball milling process [42,43,44] is an alternative way to prepare metastable materials. In the present study, the effect of the milling time and zirconia addition during high energy ball milling of bismuth oxide and zirconia powder mixtures was evaluated.

Request PDF | On Jan 10, 2014, H. S. Kwon and others published Effect of milling time on dualnanoparticulatereinforced aluminum alloy matrix composite materials | Find, read and cite all the

200 Md. Ziaul san et al.: Influence of Milling Time on Structural and Electromagnetic Properties of Manganese Doped Cobalt Ferrite Nanoparticles materials, nanoferrites have attracted the attention of researchers, scientists and technologists due to their wide

#0183;#32;It is caused due to the limited amount of energy transfer to the powder particles from the milling media up to 16 h because of small chosen rpm, BPR and limited milling time that might not be able to generate sufficient amount of dislocation in the material to fully solutionization.

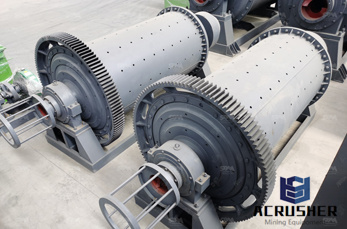

Effect Of Milling Time On Matterials. The effect of ball milling time and rotational speed on the effect of manufacturing parameters such as the effect of ball milling time and rotational speed on the final composite was analyzed by scanning electron microscopy sem, differential scanning calorimetry dsc, particle size distribution, and contact angle measurements.

Ball milling is a top down approach and a method to reduce size of particle while Zeolite is a valuable inorganic materials having wide variety of applications. In this paper, ball milling of commercial synthetic Zeolite powder was studied with their time varied. Wet ball milling was selected as a potential means to decrease the particle size of Zeolite over dry grinding.

Effect of Milling Time on Microstructure and Properties . 2015/12/01#183; T A A T Volume 60 DOI: /amm Issue 4 B. TOMICZEk*,#, DobrzAski*, M. MAcek* EFFECT OF MILLING TIME ON MICROSTRUCTURE AND PROPERTIES OF AA6061/MWCNTs COMPOSITE POWDERS The main problem of the study is the agglomeration and uneven distribution of carbon nanotubes in

Mo2NiB2Ni cermets have been extensively investigated due to their outstanding properties. However, studies have not systematically examined the effect of the powder milling process on the cermets. In this study, Mo, Ni, and B raw powders were subjected to mechanical ball milling from 1 h to 15 h. XRD patterns of the milled powders confirmed that a new phase was not observed at milling times

#0183;#32;After ball milling, the particles firstly change from spherical to irregular shape with rough surfaces, and then become granular in shape with increasing milling time. The particle size decreases with increasing milling time. It is found that the particles

Mineral xide aggregate (MTA) typically consists of Portland cement (75 wt.%), bismuth oxide (20 wt.%), and gypsum (5 wt.%) and is commonly used as endodontic cement. Bismuth oxide serving as the radiopacifying material reveals the canal filling effect after clinical treatment. In the present study, bismuth/zirconium oxide composite powder was prepared by high energy ball milling of (Bi2O3

Materials Research Express PAPER (IIHFWRIPLOOLQJWLPHRQWKHPLFURVWUXFWXUHDQG PHFKDQLFDOSURSHUWLHVRI7L amp; 1 VWDLQOHVV VWHHOFHUPHW To cite

effect of milling time on matterials. Aug 05, 2019#183; 2) The milling time has important effects on the distribution of the HEA particles, stone structure and mechanical properties of composites. When the milling time is 10 h, the best distribution of HEA particles and good mechanical properties can be price

Materials Research Express PAPER Effect of milling time on microstructure and mechanical properties of Cu Ni graphite composites To cite this article: Yiran Wang et al 2017 Mater.

The milling time were 60, 120, 180, 240, 300 and 360 minutes. The Scanning Electron Microscopy (SEM)images indicated that the microstructures and grain size of asprepared chitosan changed by

WhatsApp)

WhatsApp)