global website

global website

WhatsApp)

WhatsApp)

global website

Iron Ore Screening Solutions: As experts in understanding industry flow sheets in the mineral processing industry, our iron ore screening solutions are designed to minimise downtime and provide the lowest cost per ton processed.. Hammer Cross Belt Sampler. Our hammer samplers provide representative, cross belt samples of particulate material from a moving conveyor belt.

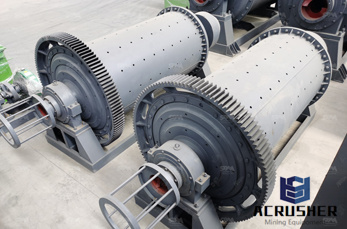

Gold Mining Ore / Mineral Processing Plant Wet Ball Mill Working Principle The transmission device drives cylinder to rotate. Materials and water are fed from the feeding end of cylinder and materials are grinded by impact and grinding of steel balls and ores into fine particles.

Ball Mill And Screening Plant Mining Iron Copper Ore Machine. iron ore concentratorre beneficiation technology is the science and technology based on physics, chemistry and biology and other disciplines, and its divided based on the features and exist forms of selected mineralshysical methods of ore beneficiation include common mineral washing, screening, reelecting, magnetic

Ball mill is a kind of grinding mill used in the mineral processing, which is to further grinding the material fitness to the appropriate particle size that meets

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about

Product Introduction A wet autogenous mill that materials as grinding media Feeding Particle Size 200350mm Product improvement Highefficiency autogenous mill can realize the second and third stage crushing and screening, and part or all crushing and grinding of rod mill or ball mil. Low power consumption, no dust pollution, less auxiliary equipment, easy production automation, and stable

Mineral processing can involve four general types of unit operation: gyratory crushers and cone crushers whereas rod mills and ball mills, The first pair of electromagnets was weakly magnetised and served to draw off any iron ore present.

Mineral processing screening of iron ore,Our company is a largescale heavy enterprise that taking heavy mining machinery manufactory as main products and integrated with scientific research, production, and marketing. We are concentrating on producing and selling machines such as jaw crusher, cone crusher, hammer crusher, ball mill, sand maker, mobile crushing plant

#0183;#32;Simulation of wet ball milling of iron ore at Carajas, (including exit classification) and experimental size distributions from wet grinding of iron ore in the pilotscale mill: lines are simulated, symbols of experimental values, see Table 3. such as that in the Modsim mineral processing

Miningpedia is a valuable and professional communication platform who focuses on providing mineral processing knowledge, mineral extraction process and the concentration of ore.

In mineral processing, this fluid is usually water, and wet classification is generally applied to mineral particles that are considered too fine (lt;200 #181;m) to be sorted efficiently by screening. As such, this chapter will only discuss wet classification.

Xinhai provides mineral processing technology, equipment manufacture and onestop service for mineral processing plant, which solve many problems for mine investors. Xinhai equipment mainly include: ball mills, flotation, thickeners, and so on.

DSO, gravity separation, Iron ore, iron ore beneficiation, magnetic separation, Beneficiation of Iron Ores. Iron ore is a mineral which is used after extraction and processing for the production of iron and steel. The main ores of iron usually contain Fe2O3 (70 % iron, hematite) or Fe3O4 (72 % iron

WhatsApp)

WhatsApp)