(PDF) Cement Manufacturing ResearchGate

Cement plants are usually located closely either to hot spots in the market or to areas with sufficient quantities of raw materials. The aim is to keep transportation costs low.

WhatsApp)

WhatsApp)

Cement plants are usually located closely either to hot spots in the market or to areas with sufficient quantities of raw materials. The aim is to keep transportation costs low.

In this process, the chemical bonds of the raw materials are broken down and then they are recombined into new compounds. The result is called clinker, which are rounded nodules between 1mm and 25mm across. The clinker is ground to a fine powder in a cement mill and mixed with gypsum to create cement.

Raw Mill Feeding Cement Plant Optimization. In any case even for free flowing materials, the angle of cone should never be less than 50 degrees to horizontal Bag filters are generally installed at the top to vent air when material is fed to a hopper Mill Feeders: Feeders for raw mills will be directly installed under hoppers with rod gate in between The feeders are generally 2 to 3 m long and

We are the manufacturers of cement plant machinery for the last 20 years and have supplied our equipments to almost all the cement plants in India amp; Abroad. Major of the equipments manufactured for cements plants are: 1. Air Separators for Cement mill, Raw mill, Coal mill

Filter Bag for Cement Plant During cement production process, there is a lot of dust and gas emissions outwardly, there are many different filter bags can be chosen for meet varied working condition. Capacity : 2000 pcs per day

Cement plants normally have sufficient silo space for 120 weeks production, depending upon local demand cycles. The cement is delivered to endusers either in bags or as bulk powder blown from a pressure vehicle into the customer''s silo. In industrial countries, 80% or more of cement is delivered in bulk. Our raw mill has been widely used in

Maintenance of Raw Mill ESP Complete Maintenance of Cooler ESP. BEST AVAILABLE TECHNIQUES FOR THE CEMENT INDUSTRY regularly cohosts conferences on specific issues aimed at improving the image of concrete and promoting the use technical data, statistics and general information on the cement industry worldwide.

Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant. There are also various other raw materials used for cement manufacturing. For example shale, fly ash, mill scale and bauxite. These raw materials are directly brought from other sources because of small requirements.

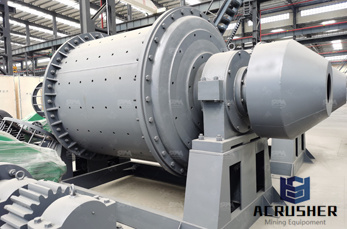

types of raw mill in cement plant. Raw Mill In Cement Plant,Cement Making Plant This mainly introduces the raw mill in cement plant In order to achieve the desired setting qualities in the finished product, a quantity (28%, but typically 5%) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker and the mixture is finely ground to form the finished cement powder

Technically, a cement producer can have almost complete control over clinker composition by blending raw materials of different compositions to produce the desired result. In practice, however, clinker composition is largely determined by the compositions of the locallyavailable raw materials which make up the bulk of the raw meal.

1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin. 1953 500th coal mill plant sold worldwide. 1961 Introduction of hydraulic spring assembly system. 1965 Construction of first pressure mill (LM D). 1980 Delivery of first modular coal mill (LM D). 1985 Delivery of first selfinerting coal grinding plant (LM D) for the steel industry (PCI

Cement kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement, in which calcium carbonate reacts with silicabearing minerals to form a mixture of calcium a billion tonnes of cement are made per year, and cement kilns are the heart of this production process: their capacity usually defines the capacity of the cement plant.

Raw mill in cement plant equipment manufacturer . Introduction of raw mill: It has many advantages such as, strong adaptability, continuous production, large crushing ratio, easy to adjust the size of the products. Raw mill is mainly used in grinding raw materials and final products in cement plant.

Engineering amp; Projects Thanks to its large experience in engineering and project management (EP, EPC...), Fives supports any kind of projects, from equipment to complete plants in greenfield, brownfield or revamping projects, providing a wide range of capabilities from design amp; materials testing up to commissioning amp; handingover.

WhatsApp)

WhatsApp)