Power Plant Coal Storage Lecture by Prof K

#0183;#32;Need for Coal Storage in a Power Plant and Different methods of Coal Storage.

WhatsApp)

WhatsApp)

#0183;#32;Need for Coal Storage in a Power Plant and Different methods of Coal Storage.

CoalFired Power Plant Construction Costs 4 projected increase in cost is consistent with other recent power plant project cost increases across the Nor are coalfired power plants that are under construction immune to further cost increases. For example, Kansas City Power

#0183;#32;In fact, we also have vibrators for our coal bunker in power plant in China, but it seems blockage still happens due to coal quality, etc, which would still cause some big problem now and again. So I wondered if any machine that have mechanical parts like a rod that put within/along the inner wall of coal bunker to loose the blockage if vibrators failed.

Hard coal and brown coal are the main energy sources for a coalfired power plant. Delivered by ship or train, the coal is unloaded into bunkers up to 30 m high. The coal is transported to these bunkers from stockpiles at the power plant via conveyer belt systems either over ground or underground.

Drills amp; Power Screwdrivers Saws Sanders amp; Planers Angle Grinders Glue amp; Heat Guns Multi Tools Plants, Seeds amp; Compost Plants Bulbs Seeds Compost amp; Bark Propagation amp; Seed Trays Hanging Baskets amp; Accessories Coal Bunkers (3) Sort By

Dry flow storage for salt, In 2019 ESI Eurosilo received the biggest order in its history with three 100,000 m3 coal silos for the EMBA Hunutlu thermal power station in Turkey. ESI recently received the biggest order in its history. As the new power plant is located in one of Turkeys precious nature reserves, the plant needs

#0183;#32;Dynegys 1,185 net MW coalfired power plant in Baldwin, Illinois started operation in 1970. The bunkers for Units 1 and 2 are both about 186 feet long, 35 feet wide and 48 feet tall.

#0183;#32;Subscribe my youtube channel to get this type of more video about tharmal power plant. Coal feeder at power plant gravimatric type Duration: 0:33. tech farm 2,755 views.

CEATETDAS03 Typical flow diagram for DM plant for 2 x 500MW coal based thermal A coal based thermal power plant consists of large number of integrated plants/systems necessary to cater to different bunker floor levels due to nonuniformity of unit sizes.

Coal Bunkers Strong, robust and durable, Carbery Plastic Coal Bunkers are ideal for the storage of a wide range of solid fuels. 3 Bag Coal Bunker 3 Bag Coal Bunker 6 Bag Coal Bunker 6 Bag Coal Bunker 12 Bag Coal Bunker 12 Bag Coal Bunker Need help in choosing

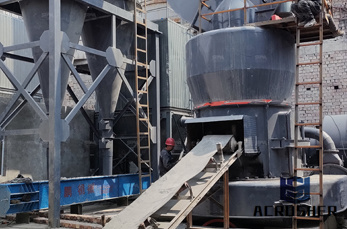

The initial process in coal based thermal power plant is coal Function of coal Handling Plant in thermal power plant is to receive, process, store, feed the coal bunkers consistently over entire life of the power plant. Coal is transported in thermal power station either by

The utility model relates to a dredging device for coal bunker blocking water cannon in a coalfired plant, which comprises a special contracting nozzle 1 on an upper layer, a pressure gauge 2, an adjustment valve 3, a shutdown valve 4, a pressure water 5, a water transfer pipe 6 and a special contracting nozzle 7 on the lower layer. Two contracting nozzles 1 are arranged in offset (opposite

Swapan Basu, Ajay Kumar Debnath, in Power Plant Instrumentation and Control Handbook, 2015. Coal Stacker and Reclaimer at the Stockyard. The crushed coal is then fed either to the coal bunkers of the main SG plant or discharged onto conveyors for storage in the coal stockyard using conveyors and transfer points. Crushed coal is sent to the stockyard when bunkers are full.

In a coal handling plant of thermal power stations there are different streams for transporting of coal up to bunker. Generally shut down is planed for a stream. Major equipment overhauls are performed during shut downs to prevent future breakdowns. Work schedules may have to be modified.

Coal fired power plants are a type of power plant that make use of the combustion of coal in order to generate use provides around 40% of the world''s electricity and they are primarily used in developing countries. Countries such as South Africa use coal for 94% of their electricity and China and India use coal for 7075% of their electricity needs, however the amount of coal

Pulverized coal storage in Bunker . Periodically a power plant may encounter the situation where coal must be stored for sometimes in a bunker, for instance during a plant shut down. The bunker, fires can occur in dormant pulverized coal from spontaneous heating within 6 day of loading.

of coal bunkers and mills for power plants and cement plants Components to be measured CO, O 2 ABB solutions AZ30 LS25 LS4000 ACX Measurement made easy Introduction Many plants like coal fired power plants, cement facilities and cogeneration industries employ coal bunkers to store coal and coal mills to crush the

chemical composition. Today, the coal flow information system KOFIS ensures constant coal quality at these locations. What KOFIS does is to provide complete tracking of batches from the time they are dumped in the power plant bunker all the way to the single boiler coal bunkers. This has made it possible to create the database needed to inspect

#0183;#32;Some plants inert bunkers/silos of PRB coal with carbon dioxide maintaining the mass flow of PRB coal. A version of this article first appeared in POWERs October 2003 issue.

WhatsApp)

WhatsApp)