Iron ore mining YouTube

8/10/2011#0183;#32;Iron Ore mining in the Plibara region of Western Australia near Newman. The Mt. Whaleback, Yandi, and Area C mines are shown.

WhatsApp)

WhatsApp)

8/10/2011#0183;#32;Iron Ore mining in the Plibara region of Western Australia near Newman. The Mt. Whaleback, Yandi, and Area C mines are shown.

Openpit mining, also known as opencast or open cut mining, is a surface mining technique of extracting rock or minerals from the earth by their removal from an openair pit, sometimes known as a borrow. This form of mining differs from extractive methods that require tunnelling into the earth, such as long wall mining. Openpit mines are used when deposits of commercially useful ore or rocks are

Iron Ore production in the Pilbara Mine operations Drill and Blast Areas for openpit mining are selected using the mine plan. Identified areas are tagged, and then holes are drilled in an appropriate pattern by rigs. The drill holes are filled with an explosive, most often ANFO (Ammonium Nitrate/Fuel Oil) and then charged.

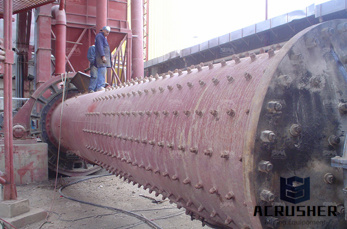

Its the largest magnetite mining and processing operation in Australia, where a high grade, premium iron ore concentrate is produced for export. It''s a fully integrated mining, processing and export operation. Using traditional open pit mining techniques, we excavate the ore and put it through a series of crushers and mills, water is added to create a slurry, along the way removing the

Openpit mining Openpit is one of the most common mining methods used and starts from the earth''s surface, maintaining exposure to the surface throughout the extraction period. The excavation usually has stepped sides to ensure the safety of the miners and a wide ramp where equipment can travel, allowing the product to be removed efficiently from the site.

CITIC Pacific Mining, Sino Iron Ore Project, Western Australia Magnetite ore is extracted using traditional open pit mining techniques we drill and blast, then use our excavators and haul trucks to cart the ore to our four inpit crushers. The open pit mine itself is currently over 3km 2 in area and will expand during the life of the mine to more than triple this size. The crushers

May 26, 2020#0183;#32;The HullRustMoning mine in Hibbing, Minnesota, is the largest openpit iron mine in Minnesota. As of 2020, material is still mined from the complex by Hibbing Taconite, or HibTac.

IOC''s production process begins in the mine with drilling and blasting. The crude ore is loaded into trucks, which dump the material into the loading pockets or into the inpit crusher located in the Luce pit.

OpenPit. As the name suggests, open pit mining involves mining minerals or ore that can be found near the surface layer of the site. That being said, some quarries can be over 1000 meters deep. This form of mining doesnt require tunnelling into the earth and is a simple method of mining that yields high production rates.

Introduction of iron open pit mining and iron processing flow. openpit magnetite mining equipment, magnetite process, iron Caimans Equipment for Openpit Magnetite Mining 57 Views. As an important raw material of iron, the magnetite plays a great role in the iron industry. Steps In The Process For Open Pit Mining Of Iron Ore In South

Mar 14, 2014#0183;#32;Drilling in the benches of open pit mining is done for production of iron ore with mechanized drills specific for each mining method. The main objective of drilling operations is to create a hole of suitable diameter, depth and direction in

1. Openpit mining. Openpit is one of the most common mining methods used and starts from the earth''s surface, maintaining exposure to the surface throughout the extraction period. The excavation usually has stepped sides to ensure the safety of the miners and a wide ramp where equipment can travel, allowing the product to be removed

Open Pit Mine In Brail Of Manganese Ore Stone Crusher Type . Open Pit Mine In Brail Of Manganese Ore Stone Crusher Type 1012. Manganese open pit mining equipment for mining equipments open srpccoin manganese mining and processing everything you need to know may 7 2014 prior to the development of advanced technology mining equipment freeing manganese from open pit

Mining Iron ore. Rio Tinto reopens pit at Tom Price mining hub after toxic gas alert. The West Australian. Thu, 14 November 2019 7:26AM Rio has now meet conditions and safety inspectors had given the all clear for work to restart. Credit: Christian Sprogoe Photography. Mining giant Rio Tinto was forced to shut down an open pit operation at its Tom Price mining hub in the Pilbara after

Metalloinvest, a leading global iron ore and HBI producer and supplier, and a major regional producer of highquality steel, has formally started up its high angle conveyor for transporting ore from the open pit iron ore mine Andrey Varichev Mikhailovsky GOK (renamed from Mikhailovsky GOK to honour the former Metalloinvest CEO who passed away recently).

Steps In The Process For Open Pit Mining Of Iron Ore In South mills in iron ore crushing and grinding process for iron ore mining are jaw crusher, crusher plant for the open pit operations and sizing of the processing plant.

Dec 16, 2020#0183;#32;Openpit mining of direct shipping hematite ore, using rotary drills, small shovels and trucks, commenced in 1963 at FDerik, Rouessa and Tazadit. Primary and secondary crushing is done at Tazadit and the ore is railed to Nouadhibou in trains of up to 220 cars, each carrying 84t.

Iron ore mining in Western Australia, the biggest single openpit iron ore mine in the world. A new town, Mount Newman, was constructed, as well as a 426 kilometre railway line, the Mount Newman railway. The first train left Mount Newman on 1 January 1969 and the first shipment of Newman ore left port on 1 April 1969 on board of the Osumi Maru. Newman remained a quot;closedquot; company town until

Open Pit Iron Ore Mining Process Mini Mill Indian Make. Details Of Iron Ore Mining Equipments. Iron ore processing plant or iron ore mining process is a relatively simple processing solutions that mainly used for iron series mimerals such as magnetite river sand quartz sand and slagshe key equipment that used for a iron ore beneficiation plant is ball mill and magnetic separator.

WhatsApp)

WhatsApp)