How Much Does It Cost To Start A Cement Plant?

Today well discuss the first part cement factory cost (or cement plant cost). According to the data we know, the total cost of a cement plant is estimated to be US 75 to US 100 per ton.

WhatsApp)

WhatsApp)

Today well discuss the first part cement factory cost (or cement plant cost). According to the data we know, the total cost of a cement plant is estimated to be US 75 to US 100 per ton.

A wide variety of cost of cement plant options are available to you, There are 1,635 suppliers who sells cost of cement plant on, mainly located in Asia. The top countries of suppliers are China, India, from which the percentage of cost of cement plant supply is 99%, 1% respectively.

cost of 500 tonnes per day cement plant india How Much Cost Is Required For Small Cement Plant, cost of 500 tonnes per day cement plant india,Although the demand gap of cement in the region is, byfar, lower than that of the average national figure, it is proposed that an MCP of 200 tonnes per day capacity shall be established Such a plant will operate 24 hours a day, and for 300 days a year

Factors affect concrete batch plant cost Materials Influence Costs Of A Concrete Batch Plant. Cement, sand, fine sand, gravel, fly ash, slag, admixture and all other materials costs can be relatively simple calculation according to the ratio and the unit price of raw material. Why raw materials will influence cost of concrete batch plant?

If you want to know mini cement plant cost in India, pleease chat online with us. Mini Cement Plant Project. All cement plants with a capacity of 200 tonnes per day or less are classified as mini cement plants. The proposed capacity of the mini cement plant is 200 mt per day (200 tpd). The unit operates in the manufacture of cement.

cost of cement plant in african countries Solar power in Africa Many perpetually sunny African nations like Egypt, Libya, Algeria, Niger, Sudan, South Africa and Namibia for instance could rely on developing their tremendous solar resources on a large scale thanks to the immense surface of their territory and at reduced pric South Africa is a leader in solar power in Africa with 1329 MW

#0183;#32;Kohat Cement Co Ltd Kohat Cement is expanding by carrying out balancing, modernisation and replacement (BMR) on a coalfired boiler power plant with the net generation of It is also setting up an additional cement grinding mill of 300tph. These projects will meaningfully reduce variable cost

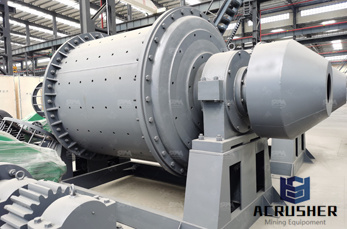

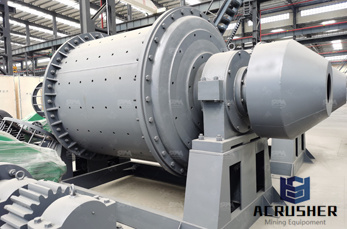

Project Cost of Mini Cement Plant. We are a supplier for crushing plant and grinding mill for mineral processing, cement production and aggregate production. We developed complete range of cement production plant, including crusher plant, ball mill, vertical roller mill, rotary kiln etc. There are also mini cement plant for sale.

Cost Of Cement Plant. as the dynamics of the cement industry change, successful companies are creating value by focusing on their micromarketseres how they do ithe bestperforming cement companies succeed by blending structural moves, such as

Hence, cement companies focus a lot in selling closer to the plants, driving sourcing and logistics efficiencies and cost reductions. This has a direct bearing on the bottom line of the companies as the industrys ability to pass on cost increases to the markets is limited due its commodity nature.

Cost profiling across geographies can help cement plant investors help to find the most profitable location to operate a plant There are a number of reasons why profiling the cost of cement factories in different geographies of the world is useful.

We will continue to manufacture the best Mining Construction Design, Low Cost Cement EPC Project, Low Cost Mine Development Plan in the industry that will delight our customers and make our employees incredibly proud of their work. Maintaining the prevailing friendly relations with our buyers, we however innovate our solution lists all of the time to satisfy the brand new demands and adhere to

The cement manufacturing plant can be divided into five steps: Crushing amp; prehomogenization: cement crusher crush limestone and other materials and stacker and reclaimer homogenize them.; Raw material preparation: use cement mill to process materials into required sizes for cement clinker production.; Clinker production: In the cyclone preheater system, the raw material powder exchange heat

Expansion plant to reduce cost 2. When a cement plant is efficiently constructed, the savings in plant construction cost translate into lower depreciation costs. 3. Growth in domestic cement demand 4. Nonengineers plant managers but with managerial skill 5. Inviting foreign technical consultants 6.

Short Answer: Around a Billion, with a B. First of all if you decided to start a cement plant from scratch today, it would probably be several years before you could turn the first shovel of dirt to start construction. You could thank the local ni...

WhatsApp)

WhatsApp)