Loesche Coal Mills Plant Sizes YouTube

#0183;#32;Loesche coal mills are mainly used in the cement industry for coal firing of cement rotary kilns. In the iron and steel industry for direct firing of coal dust into blast furnaces.

WhatsApp)

WhatsApp)

#0183;#32;Loesche coal mills are mainly used in the cement industry for coal firing of cement rotary kilns. In the iron and steel industry for direct firing of coal dust into blast furnaces.

Cement coal mill specifications. sizem, #215; separator, the ATOX coal mill will grind any Mill dimensions and characteristics. D. B. E. F. C. A.... Analysis of the Coal Milling Operations to the If you want to learn more about our Crushers and Industrial grinding mills, Coal mill specification in malaysia manufacturer coal

To summarize the coal mill controls, they may be divided basically into two major categories:. 1. To control the quality of coal being sent to the burners located on the furnace walls. The word quality here means the temperature and fineness of the PF. The set temperature values are dependent on the percentage of volatile matter that exists in the main fuel.

We specialize in coal mills: in particular performance upgrades to meet the increasing demands on South Africas power generation industry. We provide a comprehensive service for major milling plant modifications, including investigations, feasibility studies, design, manufacture, installation and

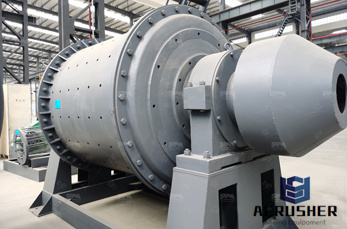

2 Mills with low rotation speed (Ball Mill with steel grinding media (ball) normally in closed circuit with classifier (in dry milling application of air separator and preheating system for

Cone mills come in various sizes, from the table top laboratory devices to the fullscale high capacity machines used for large pharmaceutical processing operations. They ensure more uniform particle size reduction is attained. The cone mills have a lower noise pollution impact and come in various designs to suit the companys demands.

Grinding mills are size reductions machines that often follow crushers in the processes where finer products are desired after crushing. Different grinding machines are usually named as mills, for example rod mills, ball mills, and attrition mills. Because of the name, verb milling is also been used as a synonym for grinding.

End Mill Size Chart (pdf) The above link provides a printable and downloadable chart of the table below. This table shows end mill diameter sizes for inch, metric, and micro milling bits from quot; to 1quot;. All of these sizes can be searched by clicking the End Mills tab at the top of the page.

mills and mill sizes for coal milling. Mills with size reduction media: Ball mills (wet) Ball mills, as described above, are also a machine of choice for milling solids in wet phase. the choice will be mainly towards an agitated ball mill or, if the milling is easy and the size different types of coal mills

#0183;#32;This is all controlled by the coal mill or pulveriser, and its associated feeder equipment. Operation of the coal mill can affect the ramp rate of the power station and its ability to handle rapid changes in output. For coalfired power plants, the response time of the coal mills is critical for the overall reaction time to changing demand.

#0183;#32;For very fine coffee grinding on our vertical Diamant mills we are able to supply the mills with special coffee stones in the sizes 400 and 500 mm. Open Catalogue. Mustard milling. The DIAMANT vertical grinding mill size 400 mm is available in a special version for milling of oily products, mustard. The mustard must be dry, not wet.

For very fine coffee grinding on our vertical Diamant mills we are able to supply the mills with special coffee stones in the sizes 400 and 500 mm. Open Catalogue. Mustard milling. The DIAMANT vertical grinding mill size 400 mm is available in a special version for milling of oily products, mustard. The mustard must be dry, not wet.

Power Stations Coal Milling Balls Large. power stations coal milling balls large Variation of coal quality and its effect on Milling plant in Coal Characteristic: Large size with Hichrome Balls for consistency in Mill

The OK Mill was originally designed for cement grinding. In 2017 we released the OK vertical roller mill for raw materials grinding. The OK Mills modular design comes with unique flexibility, showcasing parts commonality, where spare parts can be shared between vertical roller mills regardless of size

Ball Mills. Ball mills have been used for the preparation of coaloil and conventional coalwater slurry fuels, also in large sizes up to a capacity of 50 tonnes of coal per hour (Austin et al., 1984). From: Advances in Clean Hydrocarbon Fuel Processing, 2011. Related terms: Energy Engineering; Ball Milling; Grinding Mills; Mechanical

Types of coal pulverizers. Coal pulverizers may be classified by speed, as follows: Low Speed; Medium Speed; High Speed; Low speed Ball and tube mills. A ball mill is a pulverizer that consists of a horizontal rotating cylinder, up to three diameters in length, containing a charge of tumbling or cascading steel balls, pebbles, or rods.

WhatsApp)

WhatsApp)