Planetary Milling Equipment | Planetary Ball Mills MSE

Browse planetary milling equipment for sale at MSE Supplies. We carry highquality planetary ball mills, mill systems, necessary media, and more. Call Us: +1 (520) Sign in or Create an Account

WhatsApp)

WhatsApp)

Browse planetary milling equipment for sale at MSE Supplies. We carry highquality planetary ball mills, mill systems, necessary media, and more. Call Us: +1 (520) Sign in or Create an Account

There are four ball mill tanks on the planet disk. When the planet disk rotates at a high speed, the ball mill can be used as a central axis planetary motion. The ball in the ball mill can collide and rub the material vigorously during highspeed movement, so that the material is fully crushed.

The planetary ball mill has an impeccable record when it comes to grinding. The planetary ball mill is a hightech grinding machine that can finish parts in small batches by polishing and deburring them. The ball mill has some very cool safety features.

Changsha Deco Equipment Co., Ltd., Experts in Manufacturing and Exporting Planetary Ball Mill, Lab Roller Ball Mill and 321 more Products. A Verified CN Gold Supplier on

GTEK Planetary Ball Mill is designed for mixing, fine grinding, and preparing small volume hightech material product features with small volume, high efficiency and low mated with vacuum ball milling jars, it can grind samples in vacuum or inert product is extensively used in the fields of Geology, Mining, Metallurgy, Electronics, Construction Material

In a planetary ball mill, grinding occurs due to impact destruction during the motion of balls, as well as abrasion simultaneous compression and shear deformation. The size of the crushed material particles depends on the running time of the mill, the physical properties of the material, the volume of material loaded, as well as the volume of balls loaded.

Planetary ball mills are smaller than common ball mills and mainly used in laboratories for grinding sample material down to very small sizes. A planetary ball mill consists of at least one grinding jar which is arranged eccentrically on a socalled sun wheel.

Planetary Machine Grinding Planetary Ball Mill Lab 500ml * 4 Stations 2L Planetary Ball Mill Machine For Powder Mixing And Grinding. US 1380 / Set. Sets (Min Order) Xiamen Tmax Battery Equipments Limited. CN 5 YRS. % Response Rate. (33) quot;Fast deliveryquot; quot;Packed wellquot;

Planetary Ball Mills for fine grinding of soft, hard to brittle or fibrous materials. The 911MPEPB500 Planetary Ball Mills are used for fine grinding of soft, hard to brittle or fibrous materials. Dry and wet grindings are possible.

The mill develops extremely high centrifugal forces resulting in energy input that is up to 50% higher than in other planetary ball mills. It has a single grinding station for grinding jars with a nominal volume of 12 to 500 mL and can achieve a final fineness of lt;1 #181;m. The unit can store up to 10 combinations of speed, grinding time and

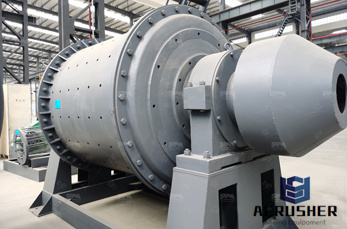

Ball Mill. The structure of our highefficient and energysaving ball mill is different from the original ball mill. The machine body and the bottom frame is integral, so that the machine can be craned and put on the base in one step. The principle axis adopts doublerow centripetal spherical roller bearing.

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of ferrous and nonferrous metals. The ball mill can grind ores and other materials either wet or dry.

ExtraFine Grinding. Planetary ball mills. A planetary ball mill consists of at least one grinding jar, which is arranged eccentrically on a socalled sun wheel. The direction of movement of the sun wheel is opposite to that of the grinding jars according to a fixed ratio.

WhatsApp)

WhatsApp)