Sepor, Inc | Gold Mining Equipment, Mine Lab Testing

Sepor, Inc. began business in 1953 with the introduction of the Sepor Microsplitter, a Jonestype Riffle splitter, developed by geologist Oreste Ernie Alessio for his own use in the lab.

WhatsApp)

WhatsApp)

Sepor, Inc. began business in 1953 with the introduction of the Sepor Microsplitter, a Jonestype Riffle splitter, developed by geologist Oreste Ernie Alessio for his own use in the lab.

offers 520 grinding machine for roller products. About 13% of these are Grinding Equipment, 9% are Flour Mill, and 7% are Mine Mill. A wide variety of grinding machine for roller options are available to you, such as key selling points, applicable industries, and warranty.

Roller press machines for pregrinding, semifinish amp; finish grinding For extreme efficiency and high equipment availability, look no further than roller press technology and products from FL. The roller press is a uniquely designed comminution tool, in that feed ore is exposed to extremely high pressure for a short amount of time resulting in a highly effective method of size reduction.

#0183;#32;Consistent grinding and balancing of rolls is necessary for efficient operation and optimum paper quality. As an integral part of a modern roll maintenance program, roll grinding and balancing uses machinery with accurate inspection and measurement equipment. This paper provides practical tips on roll inspections, balancing, grinding and grooving.

The technology''s working principle is that two counterrotating grinding rolls expose a column of material to high pressure, which is distributed across the gap between the rolls. Interparticle comminution is the HPGR specific grinding process in which material particles are crushed and ground within the compressed material bed and not by contact with the roll surface.

supplies equipment, parts and services for mining and minerals processing around the world. We have +100 years of expertise in various mining processes, such as comminution, beneficiation, material handling, and pyro processing.

If the Hydraulic Roller Press is used for finish grinding in a closed circuit with the twostage separator system, the need for other grinding equipment is eliminated. The reliable Hydraulic Roller Press outperforms ball mills and vertical mills when it comes to finish grinding.

Fine Grinding Products. Below are our most commonly used fine grinding technologies. For fine grinding solids, or grinding and drying wet cakes or pastes, our Pulvocron air classifying mill provides efficient operation and mechanical design built for easy maintenance.

Minerals has sold a KHD high pressure grinding roll (HPGR) to Goldrock Mines for Minerals has launched its new Enduron line of comminution equipment Equipment 02 JULY 2013. HPGRs in hard Equipment 31 MAY 2013. builds largest HPGR. has signed a deal to provide its new HRC3000 highpressure grinding roll (HPGR

This paper outlines an approach of equipment and process high pressure grinding roll, HPGR, roller press 2002. High pressure grinding roll utilization at the Empire mine. Mineral

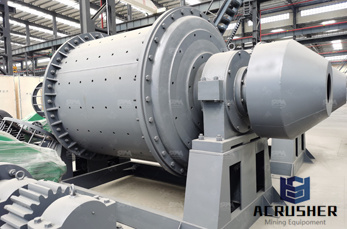

Crushing amp; Grinding Equipment. Search whose reputation for high quality lab test and mineral processing equipment is known the world over is now pleased to announce its own line of large ball mills to complement its existing line of (5 gallon size). The drive mechanism is a 1/2 HP gear motor with a variable speed, capable of roll speeds

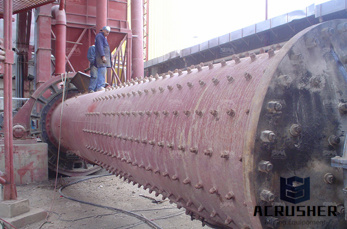

Grinding is continuous and fully integrated with subsequent flotation operations. SAG or AG mills. The crushed products are ground in SAG or AG mills. The selfgrinding machine can grind ore without grinding media such as iron ball, or steel rod, as long as the hardness of the ore is sufficient for the rolling ore to grind by itself.

WhatsApp)

WhatsApp)