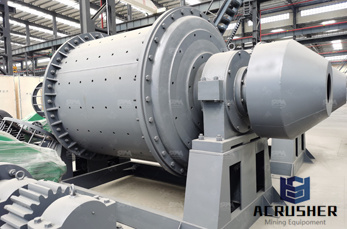

ROLLER TIRE RAYMOND Roller Tire Raymond Ball Mill

Shanghai Bogvik Wear Material Co., Ltd. Ball Mill amp; SAG Mill Parts BOGVIK is a trusted supplier of grinding mill liners and general wear +86 sales

WhatsApp)

WhatsApp)

Shanghai Bogvik Wear Material Co., Ltd. Ball Mill amp; SAG Mill Parts BOGVIK is a trusted supplier of grinding mill liners and general wear +86 sales

Product Description SAG Mill Liner from Hamp;G use CrMo materials (AS2074 S... request a quote. For inquiries about our products or pricelist,please leave to us and we will be in touch with in 24 hours. Citic SAG Mill use High Man... Impact Crusher Spare Parts Cone Crusher Spare Parts an... Jaw Crusher Spare Parts and... Grinding Ball Mill

CMI Technical Services Installation amp; Commissioning of Sag Mill amp; Ball Mill in Saudi Arabia. CMI Technical Services was specifically brought in to provide 3rd party advice and consultation services for the installation of a x SAG Mill and a Ball Mill of x dimension. MENU. Home.

ZiBo Maohua Industry Co.,Ltd. is a project engineering company that has contracted agreements with carefully selected ISO accredited foundries and machining works based in China. We manage the manufacturing of whole set equipments and components used in the mining and metallurgy industry.

Jan 14, 2019#0183;#32;Over 10 years the magnetic metal liner has been used in more than 300 fullscale ball mills at over 100 mine sites in China. For example, one set of the magnetic metal liner was installed in a (D) x m (L) secondary ball mill (60mm ball charge) at Waitoushan concentrator of Benxi Iron and Steel Corp. in 1992.

Oct 15, 2020#0183;#32;The Company has signed an agreement with Montreal based FarnellThompson Applied Technologies (FarnellThompson) for delivery of the SAG and ball mills and related parts to the PGP mill

Ball Mill leaking. Sag Mill Bolt Testing. Sag Mill Leaking. Cracked Bolts. Worn out bolt Holes When a mill is commissioned, the construction company should make sure that all the bolts are tightened to the correct load / torque to keep the flange joint tight and together during operation. If your company has a grinding mill or are going

Oleg D. Neikov, in Handbook of NonFerrous Metal Powders, 2009. Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction and kinetic energy between two or more elements vary

15/10/2020#0183;#32;Vancouver, October 15, 2020 Ascot Resources Ltd. (TSX: AOT; OTCQX: AOTVF) (Ascot or the Company) is pleased to announce it has signed an agreement for the delivery of the SemiAutogenous Grinding (SAG) and ball mills, which is critical path, long lead time equipment required in the refurbishment of the concentrator facility for restarting the past producing historic

Foundations Of Sag Ball Mill Foundation Drawings For Sag Mill . SAG is an acronym for semiautogenous grinding SAG mills are autogenous mills that also use grinding balls like a ball mill A SAG mill is usually a primary or first stage grinder SAG mills use a ball charge of 8 to 21 The largest SAG mill is 42 128m in diameter.

Manufactures Sag And Ball Mills In Canada. Ball mills steel ball mills lined ball mills particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800s the basic construction of a ball mill is a cylindrical container with journal,Manufactures Sag And Ball Mills In Canada.

Metallurgical ContentBall Charge Motion inside a SAG MillSAG Mill OperationSemi Autogenous Design FactorsSAG Mill Operation ExampleProcess Plant DescriptionSAG Mill Design and Specification Operating Problems Since CommissioningDesign Changes and Future Operating Strategies AG and SAG mills are now the primary unit operation for the majority of large grinding circuits, and form the

CONSTRUCTION. CMI Technical Services reputation has been built from its ability to deliver Ball Mill installations with a high degree of quality that ensures the Mills consistent availability during key ore commissioning phases, thus ensuring a solid move into commercial production

Once the basic operating conditions have been defined for the mill designer then, and only then, can he begin taking into account shell and head stresses and trunnion bearing sizes required to carry the load and to give the required openings for feeding and discharging the mills. Mill heads are key structural components of any grinding mill. They must carry the load of the shell assembly

Nov 30, 2020#0183;#32;The Copper Mountain mill flowsheet is currently a conventional twostage crushing, SAG, pebble crusher, ball milling, and sulphide flotation circuit design. The current capacity supports 40,000

sag mill construction contractors. sag mill construction contractors. Mill grinding Wikipedia . S is an acronym for semi autogenous grinding S mills are autogenous mills that also use grinding balls like a ball mill A S mill is usually a primary or first stage grinder S mills use a ball charge of 8 to 21 The largest S mill is 42 12 8m in diameter powered by a 28 MW 38 000 HP motor .

Ball Mill amp; Sag Mill Parts Mill Liner. Roller Tire Raymond. Roller Tire Willams. Steel Ball. Heavy Machinery Parts Bucket Tooth. Sprocket. Chocolate Bar. Track Shoes. Wear Plate. Metal Shredder Parts Hammers. Grates. Breakers and Cutter Bars. Anvils Side Liners. Caps and Hammer Pins. Pin Protectors. Feeder Wear Parts Apron Feeder Pans

ZiBo Maohua Industry Co.,Ltd. is a project engineering company that has contracted agreements with carefully selected ISO accredited foundries and machining works based in China. We manage the manufacturing of whole set equipments and components used in the mining and metallurgy industry. Specializing on the ball mill, SAG mill, AG mill designing

A wide variety of sag ball mill options are available to you, such as new. You can also choose from uzbekistan, none, and philippines sag ball mill, as well as from energy amp; mining, construction works sag ball mill, and whether sag ball mill is 1 year. There are 74 suppliers who sells sag ball mill on, mainly located in Asia.

We can refurbish your mill or convert a previouslyowned unit to meet your specific needs. For example, a ball mill may be converted into a SAG mill or a rod mill into a ball mill. Refurbishment is treated as a turnkey project starting with the removal of your mill and redesign work (when required) and moving on to manufacturing replacement

Sag Mills And Ball Mills Pdf Sag Mill And Ball Mill Of Nhi Company Mill grinding a mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting ag mills are essentially autogenous mills, but utilize grinding balls to aid in grinding li.

has experience of over 8,000 grinding mills globally, including manufacturing and delivering the largest SAG/AG mills in the world. Our experts welcome the opportunity to assist you with circuit and circuit control design as well as startup, operation, and optimization of your mill.

The style of a SAG mill liner is driven by the material of building and construction and also the application, as well as limited by casting, molding, and taking care of constraints. For huge mills with wide inlet trunnions, in excess of m, liner handling types of equipment are currently in common usage, and also this has actually permitted the development of large integral liner blocks

WhatsApp)

WhatsApp)