function of pyro in clinker plant

Cement kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement, in which calcium carbonate reacts with

WhatsApp)

WhatsApp)

Cement kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement, in which calcium carbonate reacts with

The pyroprocessing unit includes the preheater(whereby the raw meal is preheated for drying the raw material moisture), the calciner(whereby 95% of CaCO3 is decomposed to CaO+CO2), the rotary kiln(where by the remaining 5% of the CaCO3

pyroprocessing system Pyroprocessing of raw meal to form cement clinker Cooling of cement clinker Storage of cement clinker Finish Milling Packing and loading. Typical process flow of a cement plant Raw material preparation Limestone is the predominant raw material. Thats why most plants are situated near a limestone quarry in order

Cement Pakistan company is a prominent organization that support the Pakistans cement industry. In pursuit of our main objective of developing and supporting Pakistan cement industry, we have an establishment of technical and support staff, including leading authorities from cement industry, environment and engineering.

Dec 01, 2011#0183;#32;energy modeling of the pyroprocessing of clinker in a rotary cement kiln 8. energy modeling of the pyroprocessing of clinker in a rotary cement kiln 9. energy modeling of the pyroprocessing of clinker in a rotary cement kiln sankey diagram from the pyroprocessing

Today we are going to start here one very important topic Pyroprocessing in cement industry. We will understand the various terminologies and engineering concepts used in cement technology with the help of this category. Further we will go for discussion of chemistry of cement, hydration of cement, properties of cement compounds, selection of the process, process technology, burning technology, firing

In this work, firstly the energy audit was performed on the pyroprocessing unit of a cement plant in Iran to improve the efficiency of the clinker production process and operating the system. In this plant, fuel combustion is the main source of thermal energy due to generation about 94% of the total heat input energy of system that it used for

Pyroprocessing systems to improve your efficiency | FL

Cement Kiln Pyroprocessing Course. Welcome to the Cement Kiln Pyroprocessing course. The course will be published over a 6 week period and will provide 24 lectures on different topics associated with pyroprocessing in cement kilns. There will also be exercises and quizzes to assist with the learning process and exams at the end of weeks 1 to 5.

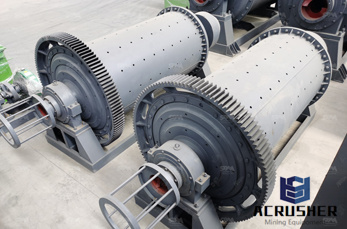

most widely used cement mill in cement pla. process plant handbook pdf cement plant for the string rotary cement kiln. pyro processing is one of the most Get Price co2 abatement in the cement industry

Today we are going to start here one very important topic Pyroprocessing in cement industry. We will understand the various terminologies and engineering concepts used in cement technology with the help of this category. Further we will go for discussion of chemistry of cement, hydration of cement, properties of cement compounds, selection of the process, process technology, burning technology, firing technology, clinker cooling

Trends in cement kiln pyroprocessing. Plant engineering companies supplying the cement industry have recently started talking about plants oriented to the needs of the customer. Attributes such as tailormade or standardized seem to be a thing of the past.

The pyroprocessing unit is central to a cement plants efficiency and uptime. Thats why so many cement producers choose a pyroprocessing system from FL. Preheater/calciner systems with industryleading low emissions

Aug 17, 1971#0183;#32;pyroprocessing operations, which constitute the core of a portland cement plant. The initial production step in portland cement manufacturing is raw materials acquisition. Calcium, the element of highest concentration in portland cement, is obtained from a variety of

Apr 15, 2019#0183;#32;China industries widely use WHRPG. Until 1989, about 35% of cement plants in china have installed the waste heat generators, and recovered energy power 30% of Chinese cements industry . During 1973 to 1978, a cement plant in the United States built five sets of lowtemperature WHRPG generators with the capacity of 500012,500 kW.

Cement Plant Suppliers. although Newell''s successors continue to make pyroprocessing equipment for less demanding applications. Get Price Energy and

Cement Production. Cement production requires the pyroprocessing of large quantities of raw materials in large kilns at high and sustained temperatures to produce clinker. From: The Utilization of Slag in Civil Infrastructure Construction, 2016. Download as PDF.

Pyroprocessing systems Fives designs and supplies pyroprocessing solutions which combine high industrial performances with sustainable development. These reliable and proven technologies reduce the operating costs amp; environmental footprint of its customer installation.

To achieve effective and efficient energy management scheme, thermal energy audit analysis was employed on the pyroprocessing unit of the cement plant. Fuel combustion generates the bulk of the

Cement Plant Technical Audit. The audit is carried out in the following steps: Make questionnaires and technical information list: The list shall be sent to the cement plant one to two weeks in advance. Site investigation: The onsite investigation generally takes 56 days.

pyroprocessing and mill in cement plant. pyroprocessing in cement plant pyroprocessing in cement plant Grinding Mill China The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help

Cement kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement, in which calcium carbonate reacts with silicabearing minerals to form a mixture of calcium a billion tonnes of cement are made per year, and cement kilns are the heart of this production process: their capacity usually defines the capacity of the cement plant.

Nov 16, 2015#0183;#32;Registered in 2018, FL Pvt. Ltd. has made a name for itself in the list of top suppliers of Cement Plant Machinery in India. The supplier company is located in Bawal, Haryana and is one of the leading sellers of listed products. FL Pvt. Ltd. is listed in Trade India''s list of verified sellers offering supreme quality of Cement Pyroprocessing etc. Buy Cement Plant Machinery in bulk

Digital technologies enable you to monitor the input materials and adjust the operation of the grinding systems and pyroprocessing system to gain the best output. As a pioneer in digitalisation in the cement industry, we have developed digital solutions for equipment control, process optimisation and plant optimisation since digital technologies were first introduced into industrial production processes.

WhatsApp)

WhatsApp)