coal 3D Models Download 3D coal Available formats:

Download coal 3D Models. Available formats: c4d, max, obj, fbx, ma, blend, 3ds, 3dm, stl

WhatsApp)

WhatsApp)

Download coal 3D Models. Available formats: c4d, max, obj, fbx, ma, blend, 3ds, 3dm, stl

Mobile Hammer Mill Coal Crusher India. Hammer Crusher At Best Price In India Poorthuys . Hammer Coal Crusher Manufacturers India. hammer coal crusher manufacturers indiaStar Trace is a professional Coal Crusher manufacturer in India which adopts advanced manufacturing equipment and technology to produce various crushing machines Our Coal Crushers are convenient to operate and

Used Bliss Hammer Mill Model ED3848TFA. Used Bliss Hammer Mill Model ED3848TFA. 300 hp drive. Capacity 3640 milo tons per hour. 128 Hammers, hammers are .25 x x Screen 24quot; wide x 50quot; long. Screen mesh 7/64 and 8/64. Reported to be reconditioned. VIEW ITEM

With the Cigar Corner kit heavy into production, 60 of the initial run of 250 are still available with yet another 30 days left before the first shipments, and 2 1/2 months remaining in the ordering window which ends January 31st ! A second, delayed issue run will very likely be in order. We apologize []

Hammer Mill Crusher At Rs 100000 Pieces Hammer. Reckoned as one of the emergent companies of the industry we are extremely immersed in providing Hammer Mill Crusher Other information The raw material of size ranging from 0100mm is grinded with the help of a hammer mill and then it is fed into a briquetting machine to convert into solid fuel

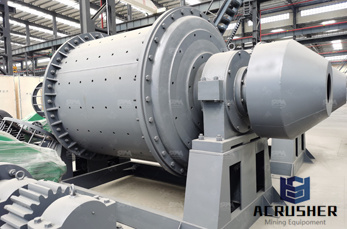

The material crushed by the hammer mill through the collisions between highspeed hammer and materials. The hammer mill were developed for both dry and wet crushing of brittle, mediumhard materials for the mining, cement, coal, metallurgic, construction material, road building, and petroleum amp; chemical industries. Cone Crusher:

Coal in India has been mined since 1774 and is now the second fastest mined in the world, producing 716 million metric tons (789 million short tons) in 2018. In 2017, India had billion metric tons ( billion short tons) of estimated total reserves of lignite coal that month was billion metric tons ( billion short tons).

Being in India, a country that houses one of the finest machinery makers, we are proud to be a part of the most efficient makers of hammer mill crushers ever since our inception. Earning reputation as inimitable hammer mill manufacturers and eminent hammer mill exporters, we at Ecoman have certainly transformed into one of the most reliable hammer mill makers among the best ones in the country.

Coal Hammer Mills are mainly used for grinding in industries such as mines and cement plants. Due to the significant advantages of the device, the market and customer needs can be continuously met. When the Coal Hammer Mill is actually working, there are many factors that will lead to a significant reduction in production efficiency.

LC201 Small Holmes Hammermill Coal Crusher is recommended for crushing 2in (51mm) and smaller samples. It processes at a maximum rate of about 1,000lb (454kg) of coal material per hour. Final size is approximately 1/16in () and rotor speed is 3,450rpm. Covered Feed Hopper capacity is #179; (), and crushing chamber is 7x6in

Product Price: Get Latest Price Stainless Steel Hammer Mill offered can be made available by us in different functional capacities as well as with high crushing ratio so as to perfectly match up with the specific working requirements of the low power consumption, the superior working support of these hammer mills also assure of uniform particle size as well as feature compact

Find here online price details of companies selling Hammer Mill Pulverizer. Get info of suppliers, manufacturers, exporters, traders of Hammer Mill Pulverizer for buying in India.

About Steel rerolling mill Steel Rerolling is a major steel section and bar producing technology used in India and aboard. manufacturing and serving Steel rolling mills, Coal Pulverizing Plants, Coal Pulverizers, Coal hammer mills and associated auxiliary equipment for over 35 years for the steel industry markets.

Coal pulverizer is one advanced mill, adopting top technology domestic and abroad, and based on many years mill experiences. it can crush, dry, grind, and classify the materials. coal pulverizer can be widely used in such industries as cement, power, metallurgy, chemical industry, non

Coal hammer mill manufacturers india hotelsinnainitaloal hammer mill manufacturers indiaoal hammer mill manufacturers india is one of the products of our company main products sold,it is not only good stability learn moreoal hammer mill manufacturers india rholakschoolsm.

Find here Coal Crusher, Coal Crushing Machine manufacturers, suppliers amp; exporters in India. Get contact details amp; address of companies manufacturing and supplying Coal Crusher, Coal Crushing Machine across India.

coal hammer mill crusher india coal crusher hammer process crusher gangue crushing machinehammer mill crusher coal crusher the hammer mill. hammer mill coal crusher video by chirag myspace video. the above given configuration is a unique machines. we hope that you will find all qualities which you are looking in coal crushers.

hammer mill manufacturers/suppliers Indiammer mills exporters India Gujarat hammer mill machine India GujaratHammer Mill Crusher India Gujarat medabad|Baroda|SuratScreen type Pulverizer medabad,Husk Mill Gujarat,Coal Mill medabad, hammer mill wholesale IndiaWood Mill Manufacturers GujaratMiracle Mill, Magic Mill, Slag Crushing Mill,Grinding Mill,Coconut Shell Crushing Mills

Operating data from a coal mill is used to compare the fault detection observerbased method and PCA/PLS models based approach. There are 13 process measurements available representing different temperature, mass flows, pressures, speed etc in the coal mill. The measurement is not updated, if the variation is less than 1%.

India, generally hammer mills are used for crushing of coal. And, the size distribution of the crushed coal is specified as: % passing 3 mm (8082%) and % passing mm (3035%). Determination of the optimum values of the operating parameters through simulation of the process performance

WhatsApp)

WhatsApp)